What Blow-Off Valve Is Right For You?

25 OCT 2024 - Jeff Willis

One of the main attractions when owning a turbocharged vehicle is that intoxicating blow-off valve noise. Now this is mainly evident in aftermarket units where companies such as HKS, Apexi, and Greddy whom pioneered these units, made them so that they could hold more boost pressure when compared to OEM units with inherent soft internal springs. More importantly, they made unique noises between shifts or when letting off the throttle. Blow-off valves really started hitting the aftermarket in the mid to late 90s when the Nissan 300ZX, the FD RX-7, and even the MKIV Toyota Supra were in the “affordable price range”. For us older folks, some of our favorite Friday past times were getting the latest issue of our local Auto Trader magazines at any 711-convenience store where we would browse for the coolest deals. In the late 90s, the biggest craze was the release of the newest at the time, Covette C5. The C5 was supposed to be the fastest car on the block. Yet in Japan, HKS and Greddy were putting said 300Z, RX-7, and Supra models on steroids with the latest developments in performance mods. During these times stateside, if you didn’t know anyone that had an aftermarket blow-off valve, you were certainly introduced to the unique sound when The Fast and The Furious debuted in 2001. It was the opening scene with the green Mitsubishi Eclipse as Brian Earl Spilner was shifting his way into early 2000s techno oblivion. Exaggerated the sound may have been as it was appropriate for the movie, it wasn’t too far off audibly. Point being for the younger folks or those new to turbocharger performance, this is a crash course in the history of how blow-off-valves became so popular in the sport compact scene. Before these times, blow-off valves were often used in high-powered turbocharged vehicles that Porsche challenged with their line of 911 turbos, 962 models, and Audi in Groupe B Rally Racing. In the early 90s when enthusiasts who wanted to go fast and be competitive but didn’t have the budget for a new 911 turbo, they resorted to 1st-generation DSM Mitsubishi Eclipse, Eagle Talon, and Plymouth Laser models, and figured out how to make these things really fast. One of the problems that they had to iron out with bigger boost was battling boost leaks.

HOW DOES A BLOW-OFF VALVE WORK?

Look at this turbocharger for example:

Grimmspeed Overtake BB500 Turbocharger Kit 2002-2014 WRX / 2004-2021 STI

Take this turbocharger for example. And this applies to turbocharged vehicles across the board. As the turbo sucks in air, the cover aka compressor cover, forces an air charge through the intercooler where the intake charge temps are cooled, just before entering the intake manifold. This is of course, happening when the turbocharger is spooling during wide open throttle, or even at enough throttle where the turbo is spooling. The compressor wheel spins at such a high rate that when you let off the throttle for shifts or deceleration, the throttle plate in the throttle body closes. The excess air getting pushed through the intercooler pipes has no where to go, so the intake uses vacuum to open the blow-off valve, releasing the excess air pressure, or boost. If you do not have a blow-off valve, you would otherwise experience compressor surge.

WHAT IS COMPRESSOR SURGE?

Compressor surge is where while the turbo is in boost, and when you shift or decelerate allowing the throttle body to close, the air cannot escape the blow-off valve fast enough so the air gets forced back to the turbocharger which can interrupt the spool function. Excessive compressor surge can lead to premature turbocharger wear because you are also interrupting the balance of the turbo shaft with the reversal of air fighting against the compressor wheel. Although the sound is also intoxicating, it does have a similar sound to a blow-off valve with a soft spring:

WHEN SHOULD I UPGRADE MY BOV?

There are two reasons. The first reason is the obvious and that is because you love the sound. More importantly will be the second reason, and that is because you’re overpowering your OEM blow-off valve. How does that happen? One of the reasons is that you are making more horsepower that overpowers the internal spring of the OEM blow-off valve. When this happens, you are leaking boost and are not hitting your targets. All aftermarket units will have an internal spring that is stiffer than the OEM unit. And blow off valve examples such as Tial’s design allows you to add a variety of spring rates to accommodate your boost levels:

Tial QR Recirculating Blow-Off Valve - Universal

And Tial’s example is for those of you who opted to go with front mount intercooler kits and will have a blow-off valve flange welded on the intercooler piping. Now to be fair and to appease the minimalists, the OEM blow-off valve is good enough for basic performance upgrades such as an intake, cat-back, and a tune. Once you start reaching that 350 HP mark, then an aftermarket unit will ensure that your blow-off valve is holding boost. The spring will be strong enough to keep the valve closed, and as your throttle body shuts, your intake will pull enough vacuum on the blow-off valve to open enough to relieve the pressure.

WHAT IS RECIRCULATING VS NON-RECIRC?

Recirculating means that on the majority of OEM blow-off valve designs, the relieved pressure from the blow-off valve will go back into the intake manifold. Now it has been debated that recirculating blow-off valves keep the turbocharger wheel spinning between shifts, then others argue that the tune will run richer if you have a blow-off valve that vents to the atmosphere.

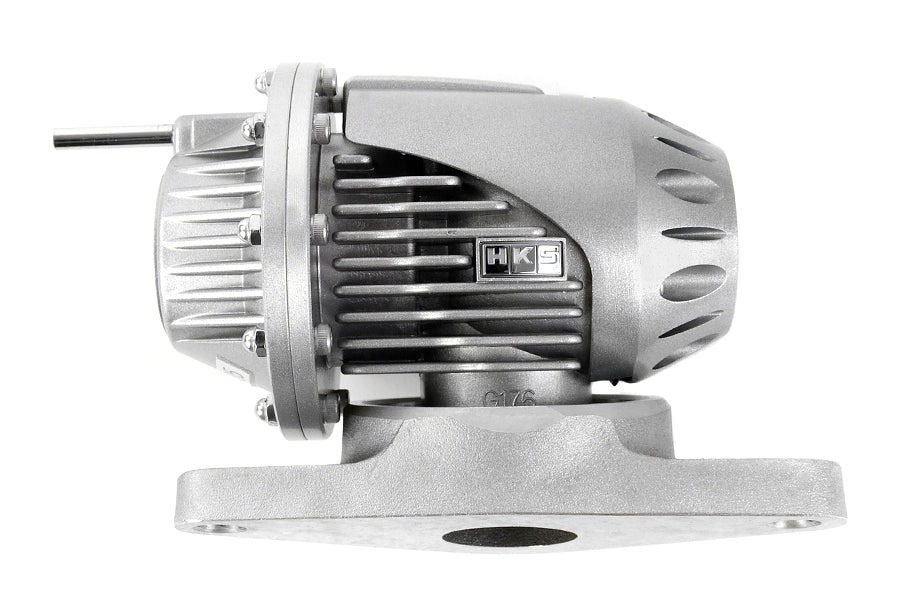

What it really boils down to is personal preference. You either want the noise, or you don’t. If you want the loud noises, get something such as the most famous blow off valve, the HKS Super Sequential Blow Off Valve. Also known as the bird chirper:

HKS Super SQV4 Blow-Off Valve 2002-2007 WRX/STI

</p>

Yet at the same time if you want the performance but don’t want the sound, HKS makes the same blow-off valve with a recirculation kit:

HKS Super SQV4 Blow-Off Valve w/Recirculation Kit 2008-2014 STI

And companies such as Go Fast Bits makes adjustable units so that you can control how loud of the sound suits your personal preference:

Go Fast Bits Respons TMS Adjustable BOV 2015-2021 Subaru WRX

THE VERDICT:

The fact of the matter is that there is a performance benefit with aftermarket blow-off valves. They hold boost better when compared to the OEM unit because they have a stiffer internal spring. Now you must consider how much horsepower you are running as well. The majority of modded Subarus will be at the 350 HP otherwise you need to have a built motor to sustain 400 WHP. At 350-400 any aftermarket will be fine. But 600 HP on a rotated kit with larger injectors, multiple pumps, and a standalone, you should run something where you can change out the springs such as a Tial unit.

The other key consideration is the sound. Some of you love the loudness of blow-off valves that vent to the atmosphere, whereas others want something recirculating on the quiet side.

One thing is for certain, here at SubiSpeed, we have plenty of options for you to choose from. Here are some honorable mentions that might suit your needs:

Turbosmart Dual Port Blow Off Valve 2015-2024 WRX

PERRIN Recirculating Blow-Off Valve 2008-2014 WRX

GrimmSpeed Bypass Valve 2008-2014 WRX

COBB Tuning LF Bypass Valve 2002-2007 WRX / 2004-2021 STI

Turbosmart Kompact EM Plumb Back Blow-Off Valve 2022-2024 WRX